Welded Wire Mesh

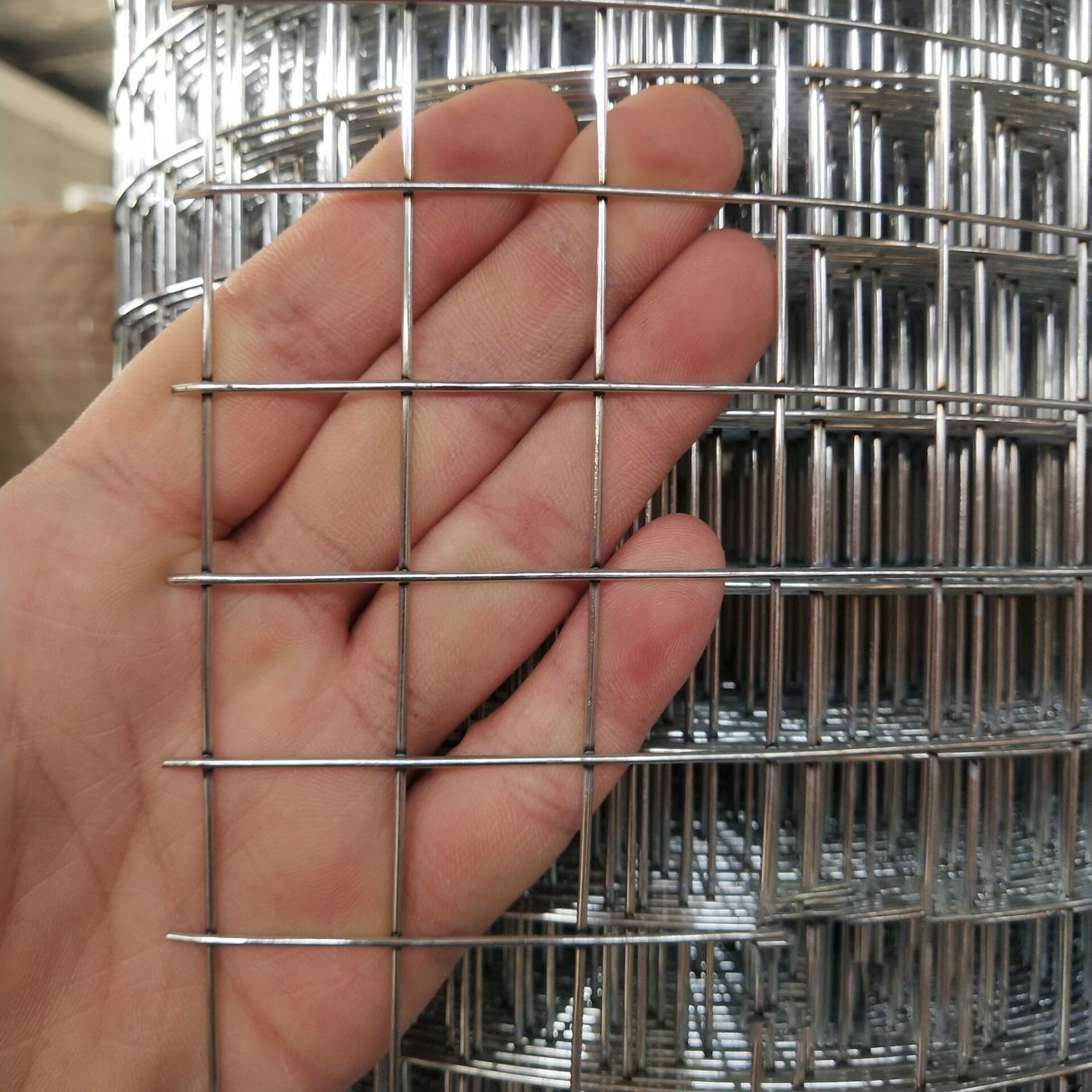

The welded wire mesh is made of carbon steel wire by automatic mechanical spot welding.It's one of the most widely used types in metal meshes. with a flat mesh surface, uniform mesh holes, firm welding, and strong anti-corrosion and oxidation resistance.In terms of shape, it can be divided into mesh rolls and mesh sheets. Assortments available: (1)hot dip galvanized welded wire mes...

hiddenValue

- Description

-

The welded wire mesh is made of carbon steel wire by automatic mechanical spot welding.It's one of the most widely used types in metal meshes. with a flat mesh surface, uniform mesh holes, firm welding, and strong anti-corrosion and oxidation resistance.In terms of shape, it can be divided into mesh rolls and mesh sheets.

Assortments available:

(1)hot dip galvanized welded wire mesh

(2)electro galvanized welded wire mesh

(3)PVC coated welded wire mesh

(4)stainless steel welded wire mesh

(5)black iron welded wire mesh

Welded Wire Mesh

Welded wire mesh, or welded wire fabric is a steel reinforcement material in concrete. The mesh is used for

replacing the traditional "cut & bend" and placing of steel

thermo-mechanical treated bars. The mesh is an electric fusion welded

prefabricated reinforcement consisting of a series of parallel

longitudinal wires with accurate spacing welded to cross wires at the

required spacing. Machines are used to produce the mesh with precise

dimensional control. The product results in considerable savings in

time, labour and money.

Welded wire mesh, or welded wire fabric is a steel reinforcement material in concrete. The mesh is used for

replacing the traditional "cut & bend" and placing of steel

thermo-mechanical treated bars. The mesh is an electric fusion welded

prefabricated reinforcement consisting of a series of parallel

longitudinal wires with accurate spacing welded to cross wires at the

required spacing. Machines are used to produce the mesh with precise

dimensional control. The product results in considerable savings in

time, labour and money.

Use: The welded wire mesh is a metal screen that is made up of low carbon steel wire or stainless steel wire. It is available in various sizes and shapes. It is widely used in agricultural, industrial, transportation, horticultural and food procuring sectors. It is also used in mines, gardening, machine protection and other decorations.

Type: Galvanized welded wire mesh, Stainless steel welded wire mesh, PVC coated welded wire mesh.

Welded Wire Mesh Panel

What Are Welded Wire Mesh Sheets?

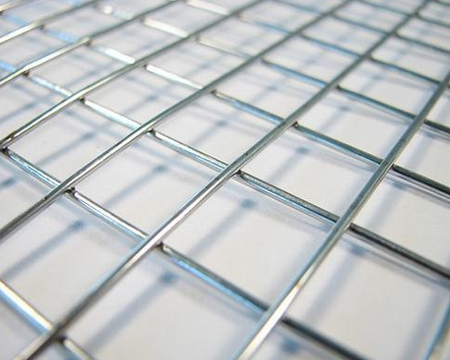

Welded wire mesh sheets are created from wires that are welded together at their cross points to form a grid-like pattern. The welding technique used is resistance welding to properly create a sheet from raw materials. The wires of the grid are guided through using a pattern board which allows the two planes of wires to form and fuse into a complete welded wire mesh sheet.

What Raw Materials Are Used?

Many different raw materials can be used to create welded wire mesh sheets. The basis of choosing what material depends on the application and setting that the finished welded wire mesh sheets will be used for.

One form of raw material that can be used is plain steel. Plain steel has a fairly low carbon content rating and is known for its value for the price. However, plain steel can rust easily if used in certain outdoor conditions.

Another form of raw material that can be used is stainless steel. Stainless steel is pricier than plain steel but more durable. Stainless steel is resistant to corrosion and offers aesthetic properties that soothe many tastes. Stainless steel is resistant to corrosion due to the presence of chromium in the chemical makeup.

Weathering steel is a raw material that can be used in the creation of welded wire mesh sheets as well. Weathering steel is utilized when natural weathering from the earth is a concern. Weathering steel develops a rust-like color when under the influence of weathering to help protect the structure of the steel.

Pre-galvanized is a form of a raw wire that has a zinc coating applied before the welded wire mesh sheets are developed. Pre-galvanized is a tiny bit more expensive than the cheapest option of plain steel. The pre-galvanized material has slightly more corrosion resistance properties and is a better base for powder coating and other aesthetic finishes.

No matter the raw material used, a variety of finishes can be performed that enhance aesthetics or add extra protection to the welded wire mesh sheets. Some of these finishes include powder coating, plating, and dipping.

Keywords:

Keywords:- Welded Wire Mesh

About Us

Your Premier Source for Quality Metal Wire Products

Discover excellence in construction essentials!

We specialize in distributing Rebar Tying Machine fitting wire, various metal wire mesh, and top-notch nail products. With over 20 years of global export experience, we serve industrial and commercial needs worldwide. Our mission: 'Quality First, Customer First, Reputation Above All.' Rigorous testing ensures only the best products reach our valued customers. Elevate your projects with our trusted solutions.

Send Inquiry

NOTE: Please leave your email, our professional person will contact you asap!

Related Product